Design and Manufacturing Services

OEM / ODM Design & Manufacturing Services

Processing procedure

NEWTIDE provides comprehensive OEM / ODM design and manufacturing services, covering every stage from product design and development to mass production and quality management.With advanced technology, strong R&D capabilities, and a professional engineering team, we deliver customized, high-quality solutions that improve efficiency, reduce costs, and enhance market competitiveness.All processes strictly comply with ISO 9001, ISO 14001, RoHS, and REACH standards, ensuring reliable performance and sustainability. Our products and services serve a wide range of industries, including electronics, machinery, and consumer goods.

By partnering with NEWTIDE, clients can accelerate time-to-market, ensure stable product quality, and gain stronger competitive advantages in today’s fast-evolving global market.

SERVICE.01

Electroplating

Our professional electroplating services deposit high-quality metal coatings (Gold, Silver, Nickel) on connector pins and shells. This enhances conductivity for low-resistance signal transmission and provides corrosion resistance for durable audio connections.

01

SERVICE.02

Anodizing

We offer premium anodizing to form a protective oxide layer on aluminum connector shells. This improves wear resistance and allows for vibrant color-coding (e.g., Red/Blue/Black), which is essential for channel identification in professional audio and video cabling systems.

02

SERVICE.03

Baking Paint

Our spray coating and heat-curing process creates a smooth, durable finish for microphone bodies and audio equipment chassis. We provide specialized coatings that resist scratching and corrosion, maintaining the aesthetic appeal of stage and studio gear.

03

SERVICE.04

Electrophoretic Coating

E-coating applies a uniform, non-conductive black finish even on complex connector geometries. It offers excellent environmental protection and is widely used for black-finish XLR and TRS connectors where a sleek, non-reflective appearance is desired for stage use.

04

SERVICE.05

Screen Printing

Specialized printing technology for transferring crisp markings onto flat panels. We ensure clear labeling of I/O ports, channel numbers, and branding logos on audio interfaces and rack-mounted equipment, using wear-resistant inks that withstand frequent handling.

05

SERVICE.06

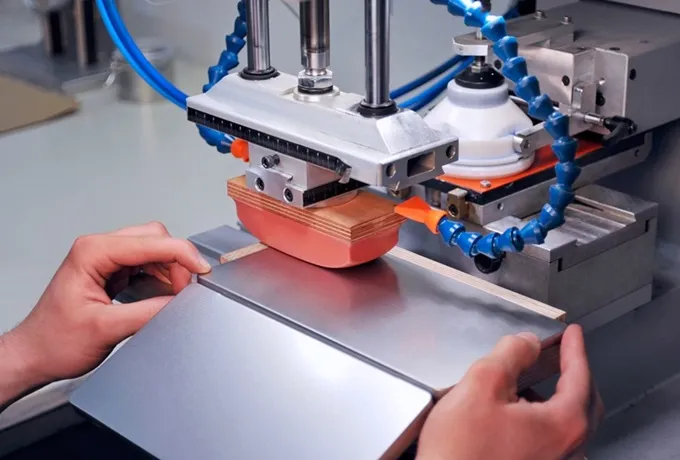

Pad Printing

Utilizing flexible silicone pads, our pad printing service transfers detailed logos and model numbers onto curved surfaces. This is the ideal solution for branding cylindrical connector bodies (like XLR/TRS shells) where flat printing methods cannot be used.

06

SERVICE.07

Dispensing & Potting

Precise application of resins and sealants to insulate and protect cable assemblies and connectors. Our potting process provides IP-rated waterproofing and strain relief, ensuring reliable signal transmission for outdoor and stage audio equipment.

07

SERVICE.08

Laser Engraving

High-precision laser technology for creating permanent markings on metal connector shells. We specialize in engraving batch codes, serial numbers, and brand logos on XLR, BNC, and other connectors to ensure traceability and professional branding.

08