Why Is Pin 1 on an XLR Connector Designed to Make Contact First?

The Engineering Logic Behind “First Make, Last Break” Meta Description:Why is Pin 1 on an XLR connector designed to protrude

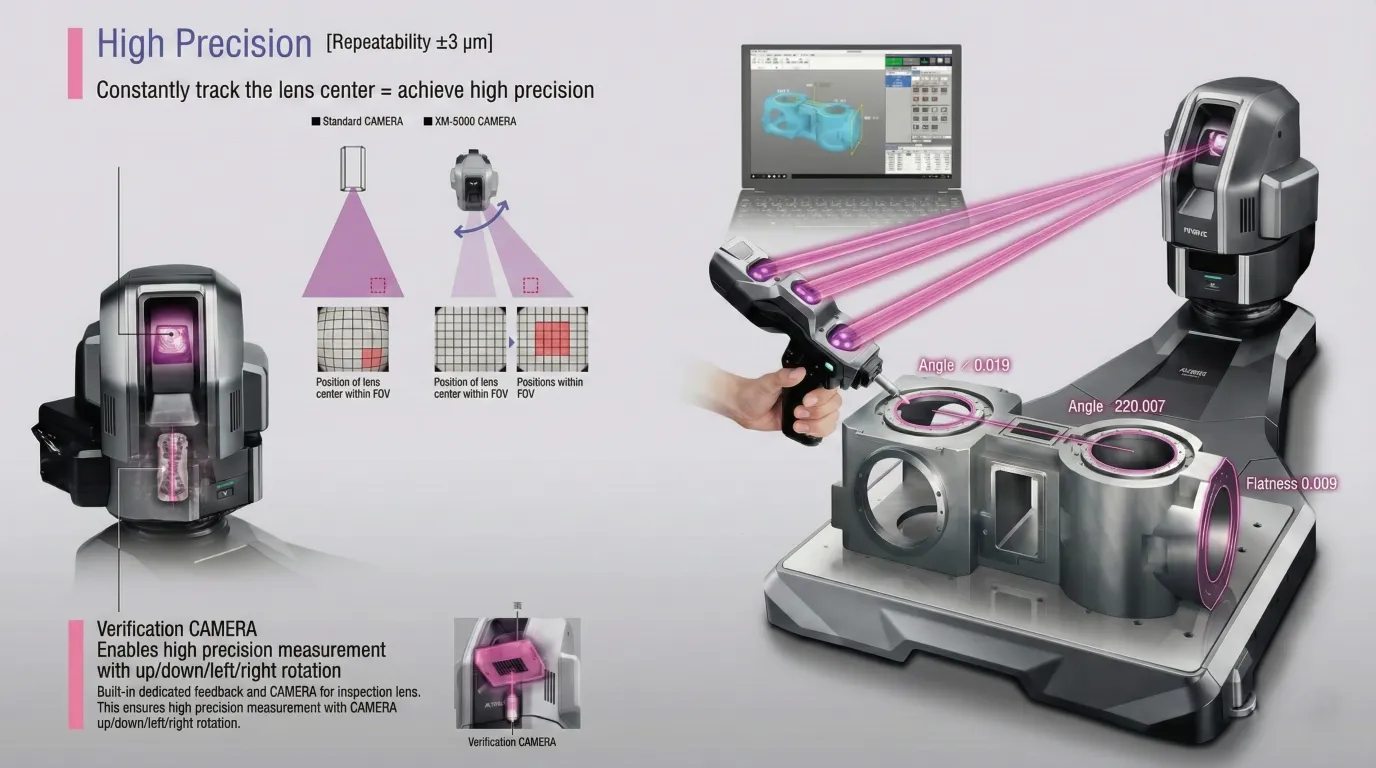

In response to the increasingly stringent standards of global precision manufacturing, NEWTIDE Enterprise Co., Ltd., a premier designer and manufacturer of professional connectors, officially announces the successful deployment of the Keyence XM-5000A Handheld Probe Coordinate Measuring Machine (CMM) as of June 2022. This strategic investment marks a significant leap forward in NEWTIDE’s Quality Management System (QMS), aiming to optimize process control through laboratory-grade inspection capabilities and high-efficiency on-site measurement, thereby delivering competitively superior precision products to global clients.

Conventional inspection processes for precision parts are often constrained by the rigid requirements of fixed gantry CMMs, which necessitate moving workpieces to temperature-controlled rooms. This is not only time-consuming but also presents logistical challenges for large or geometrically complex components, such as large CNC machined parts or molds.

The introduction of the XM-5000A system addresses these technical challenges head-on. By integrating innovative “Movable Camera” and “Handheld Probe” technologies, the system delivers key operational advantages:

NEWTIDE specializes in the manufacturing of high-end XLR, RCA, and BNC connectors, as well as OEM/ODM precision parts. These products typically feature complex curved surfaces, intricate bore holes, and rigorous geometric tolerance requirements (such as coaxiality, flatness, and roundness).

Compared to traditional manual tools like calipers or height gauges, achieving extreme precision for complex geometric features in 3D space is challenging and prone to human error. With the XM-5000A’s Free-Angle Probe, inspection personnel can flexibly access internal bores, slopes, or side features using a handheld stylus. The system automatically reconstructs a 3D model and outputs precise data.

Furthermore, the system supports advanced 3D CAD Comparison Analysis. NEWTIDE’s engineering team can import original design files directly into the system for real-time overlay comparison with the physical part. The resulting full-color deviation map (Color Map) provides a visual representation of machining errors. This function not only drastically shortens the First Article Inspection (FAI) cycle but also significantly enhances the precision and efficiency of reverse engineering and mold correction.

“Quality is the core value of NEWTIDE.” Since the introduction of the Keyence XM-5000A in 2022, the company has not only upgraded its hardware facilities but has also transitioned towards a data-driven and visualized quality management approach. The instrument automatically generates inspection reports with images and Statistical Process Control (SPC) charts (such as Trend Charts, Histograms, and Cpk Process Capability Analysis), ensuring complete traceability of quality data.

For NEWTIDE’s global partners, this technological upgrade translates into tangible benefits:

As the trend towards Industry 4.0 and smart manufacturing advances, NEWTIDE Enterprise will continue to invest in the R&D and application of advanced manufacturing and inspection technologies. The introduction of the Keyence XM-5000A is merely a milestone; looking ahead, the company remains committed to process optimization and the implementation of ISO 9001 and ISO 14001 standards. With “Zero Defects” as the ultimate goal, NEWTIDE is dedicated to becoming the most trusted strategic partner in the global connector and precision machining sector.

About NEWTIDE Enterprise Co., Ltd.

Established in 1989, NEWTIDE is a leading connector manufacturer in Taiwan, providing one-stop solutions from design and R&D to mass production. Its products are widely used in audio, video, medical, and industrial instrument sectors, renowned for their excellence in quality and high reliability.

NEWTIDE — Precision in Every Detail.

The Engineering Logic Behind “First Make, Last Break” Meta Description:Why is Pin 1 on an XLR connector designed to protrude

Audio connectors (commonly known as Phone Jacks) are defined by far more than their physical size. Behind each connector lies

🌟Introduction: The Gold Standard of Professional Connectivity In professional audio, broadcast, and stage lighting systems, the XLR connector is far