Design and Manufacturing Services

OEM / ODM Design & Manufacturing Services

Manufacture and production

NEWTIDE provides comprehensive OEM / ODM design and manufacturing services, covering every stage from product design and development to mass production and quality management.With advanced technology, strong R&D capabilities, and a professional engineering team, we deliver customized, high-quality solutions that improve efficiency, reduce costs, and enhance market competitiveness.All processes strictly comply with ISO 9001, ISO 14001, RoHS, and REACH standards, ensuring reliable performance and sustainability. Our products and services serve a wide range of industries, including electronics, machinery, and consumer goods.

By partnering with NEWTIDE, clients can accelerate time-to-market, ensure stable product quality, and gain stronger competitive advantages in today’s fast-evolving global market.

STEP.01

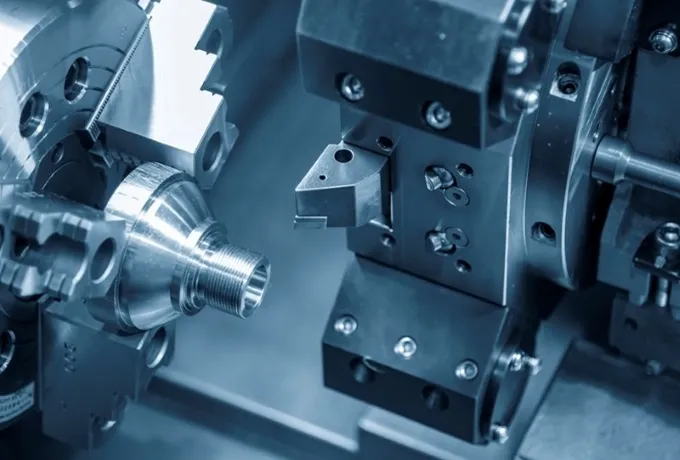

CNC Lathe

Utilizing advanced CAD/CAM technology, our automated CNC lathes deliver high-precision cylindrical parts for connectors. We specialize in machining brass, aluminum, and stainless steel bodies for XLR, TRS, and RCA connectors. Our process ensures tight tolerances and consistent quality from prototyping to mass production.

01

STEP.02

Zinc Alloy Die Casting

Zinc alloy casting offers superior strength and EMI shielding properties, making it the standard for professional audio connector shells (e.g., XLR, TRS). We produce precision housings with smooth finishes ready for plating, ensuring durability and signal integrity for high-end audio equipment.

02

STEP.03

Aluminum Alloy Die Casting

Combining lightweight properties with high durability, our aluminum die casting process is ideal for manufacturing audio equipment chassis and connector panels. We deliver complex geometries that support secondary finishes like anodizing, perfect for stage boxes and rack-mounted audio interfaces.

03

STEP.04

Plastic Injection Molding

We provide efficient injection molding solutions for thermoplastic products, specifically focusing on high-performance connector insulators and housings. Our capabilities ensure precise dimension control for reliable pin alignment in multi-pin connectors used in professional broadcasting and electronics.

04

STEP.05

Rubber Molding

Offering compression and injection molding for custom rubber parts like cable strain reliefs (boots) and sealing gaskets. We use flexible elastomers to ensure durability and cable protection for microphone cables and audio interconnects, preventing wear and signal loss.

05

STEP.06

Metal Stamping

Utilizing high-speed presses and progressive dies, we specialize in manufacturing high-conductivity connector contacts, terminals, and ground springs. Our stamping process ensures tight tolerances for optimal electrical performance in audio and video transmission interfaces.

06