🎧The Ultimate Guide to Audio Connector Standards: 6.3mm, 3.5mm, 2.5mm, and 4.4mm Explained

Audio connectors (commonly known as Phone Jacks) are defined by far more than their physical size. Behind each connector lies

Meta Description:

Why is Pin 1 on an XLR connector designed to protrude or engage first? This article explains the “First Make, Last Break” principle and how it protects audio equipment, reduces pop noise, and ensures proper grounding and EMI shielding. Essential reading for audio and connector design engineers.

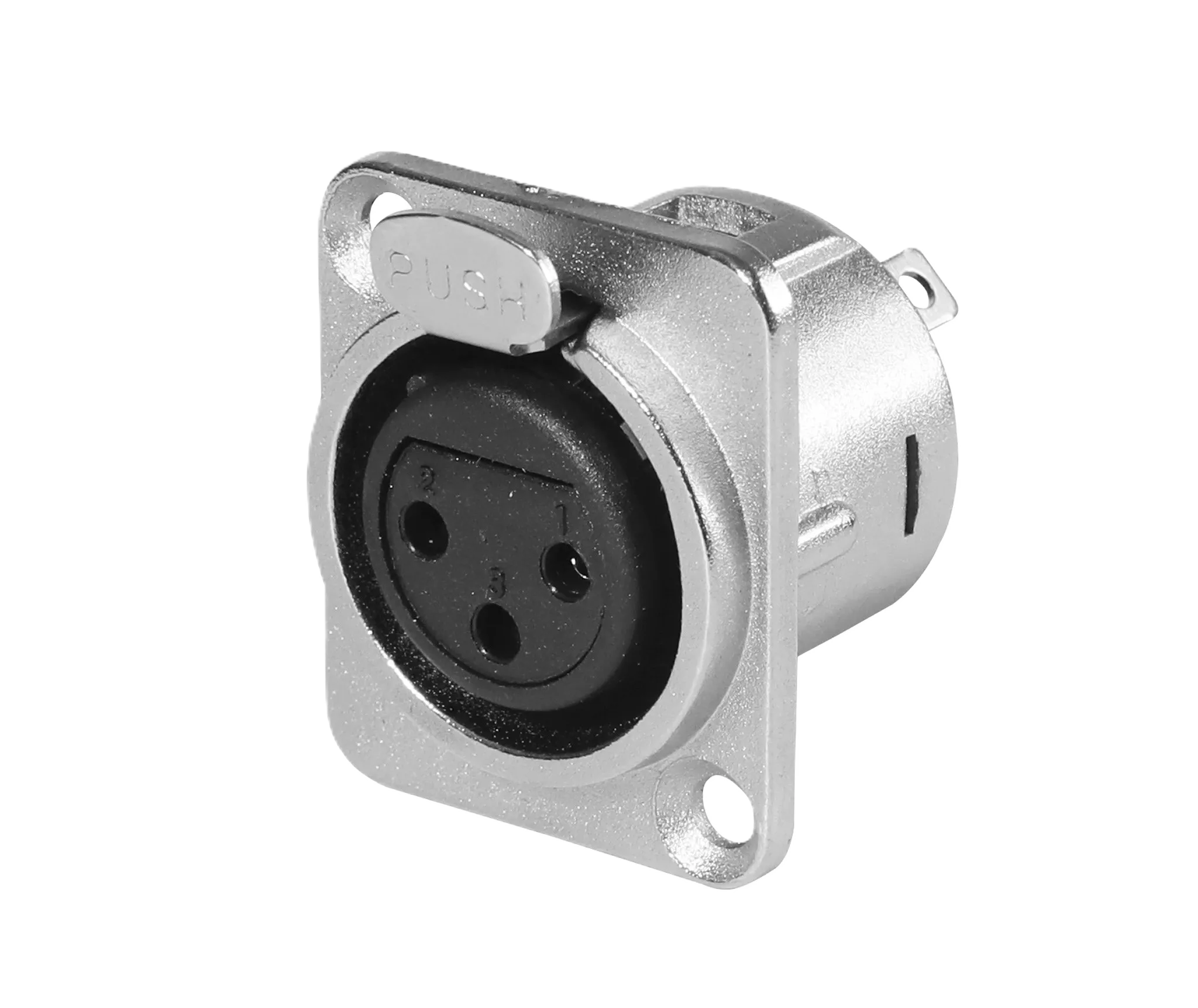

In professional audio and broadcast systems, the XLR connector (commonly referred to as a Canon connector) is the industry standard for balanced signal transmission. If you closely inspect a high-quality XLR male connector or examine the internal structure of an XLR female connector, you will notice that Pin 1 is intentionally designed to make contact before Pins 2 and 3.

This priority contact may be achieved by:

This is not a manufacturing tolerance issue or a design flaw. It is a deliberate engineering decision. A difference of just a few millimeters can determine whether expensive audio equipment remains protected—or whether loud pop noises or even component damage occur during connection.

This article explains the rationale behind this design from both mechanical engineering and electrical behavior perspectives.

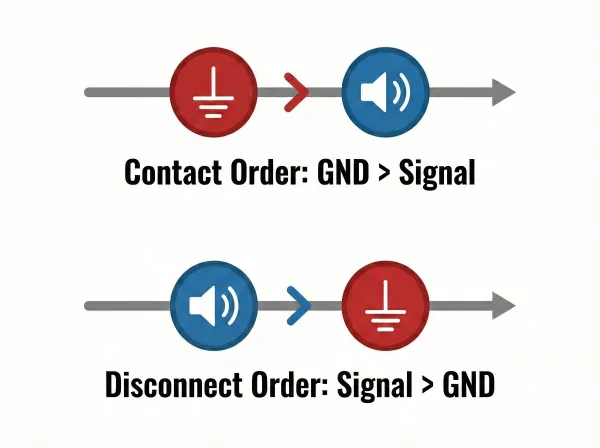

The primary purpose of prioritizing Pin 1 is to implement the First Make, Last Break (FMLB) contact sequence.

This sequence is fundamental to the reliability and safety of professional audio systems. Its importance can be understood across three key engineering domains.

Before two audio devices are connected—such as a microphone and a mixer, or a preamp and a power amplifier—there may be a potential difference between their chassis grounds. Additionally, static electricity may be present on the cable or the user.

If signal pins were to connect first:

The role of Pin 1:

Pin 1 is typically bonded to the device’s chassis ground. By making contact first, Pin 1 equalizes the electrical potential between devices and safely discharges static energy before any audio signal path is established. This acts as the first and most critical layer of protection.

Many users are familiar with the loud “pop” that occurs when inserting TS or TRS connectors into an active audio system. This happens because the signal path is momentarily energized before a stable ground reference exists.

The XLR FMLB design minimizes this risk by:

As a result, XLR connectors are designed to support hot plugging, even when +48V phantom power is enabled.

From an operational standpoint, muting the channel before connection is still recommended as an additional safeguard, but this is a procedural precaution—not a design limitation.

Balanced signal transmission already provides excellent noise rejection. However, Pin 1 is directly connected to the cable shield.

When Pin 1 makes contact first:

This ensures that the signal conductors are protected from electromagnetic interference (EMI) and radio-frequency interference (RFI) at the very moment the connection is established.

XLR connector geometry and interfaces are defined under IEC 61076-2-103. While AES14 primarily addresses grounding and shielding practices rather than mechanical contact sequencing, its engineering philosophy aligns closely with the First Make, Last Break approach.

For this reason, major professional connector manufacturers such as Neutrik and Switchcraft implement Pin 1 priority contact through:

This approach is widely recognized as industry best practice.

Q1: Do all XLR connectors use this design?

A: Most professional, standards-compliant XLR connectors do. Extremely low-cost or non-standard products may omit this feature, increasing operational risk.

Q2: What happens if Pin 1 does not connect first?

A: At minimum, loud pop noises may occur during connection. In more severe cases, static discharge or voltage transients can damage sensitive audio circuitry—especially when phantom power is present.

Q3: Is this related to the “Pin 1 Problem”?

A: Yes. Regardless of how Pin 1 is routed on the PCB, its physical First Make, Last Break behavior ensures that shielding and potential equalization occur before the signal path is energized. This is the first line of defense at the hardware level.

The priority contact design of Pin 1 in XLR female connectors is a textbook example of “form follows function” in audio engineering. A subtle mechanical detail enables effective static protection, pop noise reduction, and shielding integrity—all without adding circuit complexity.

For engineers focused on high-reliability audio products, strict adherence to the First Make, Last Break principle is not merely a standards issue—it is a commitment to equipment safety and professional performance.

Audio connectors (commonly known as Phone Jacks) are defined by far more than their physical size. Behind each connector lies

🌟Introduction: The Gold Standard of Professional Connectivity In professional audio, broadcast, and stage lighting systems, the XLR connector is far

Introduction The BNC connector (Bayonet Neill–Concelman) is a widely adopted radio‑frequency (RF) coaxial connector used throughout professional electronics, broadcasting, surveillance,