Why Is Pin 1 on an XLR Connector Designed to Make Contact First?

The Engineering Logic Behind “First Make, Last Break” Meta Description:Why is Pin 1 on an XLR connector designed to protrude

Deepening Our Commitment to Quality Assurance in Precision Manufacturing

In the precision manufacturing and processing industry, Quality Control (QC) is not only the final defense for ensuring product compliance but also the cornerstone of NEWTIDE’s commitment to our clients. To further optimize product yield and enhance inspection efficiency, NEWTIDE officially announced the implementation of the industry-leading Keyence LM-1100 High-Precision Image Dimension Measurement System in June 2022. This strategic equipment upgrade marks the official entry of our quality management system into a new era of automated inspection with “Sub-micron” precision.

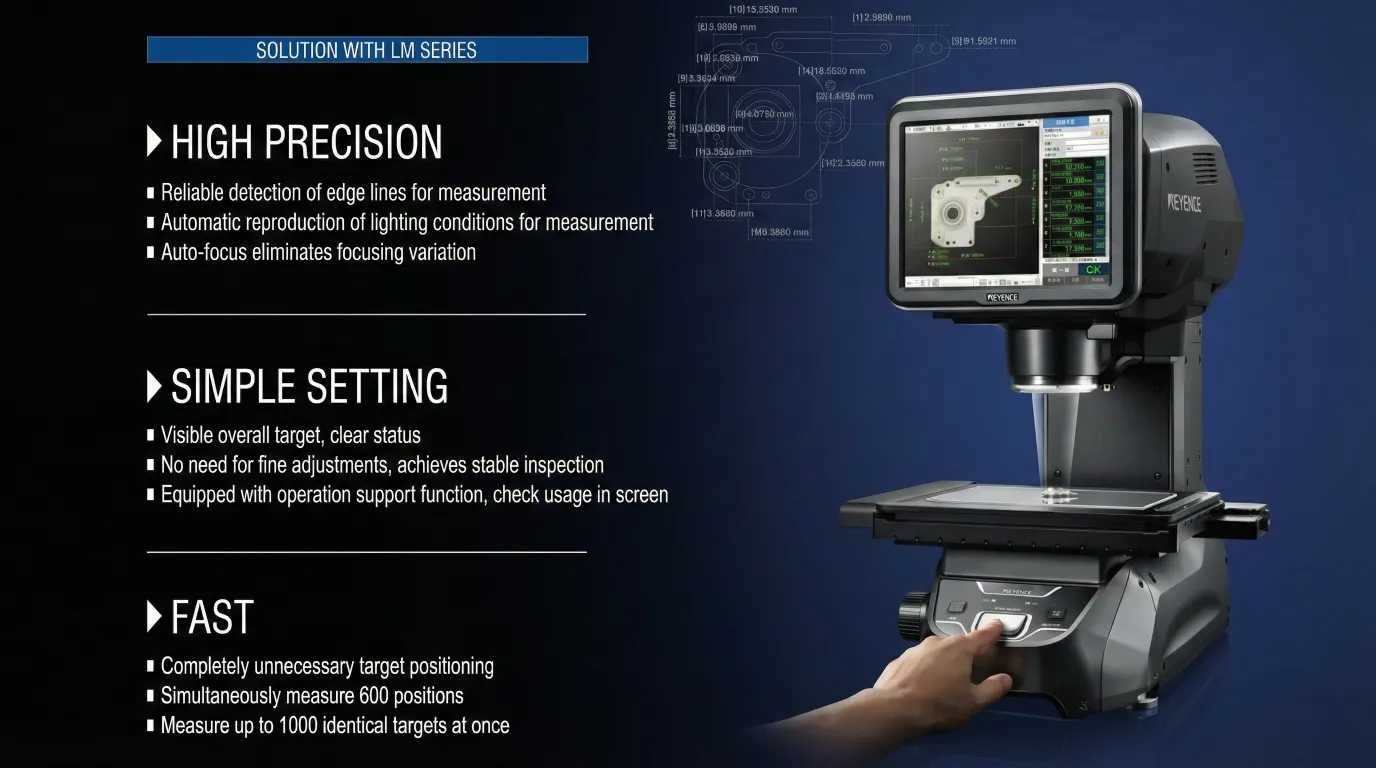

By introducing this advanced measurement system, NEWTIDE aims to resolve the human error and efficiency bottlenecks associated with traditional manual measurement or legacy projection equipment. According to the manufacturer’s technical specifications, the LM-1100 empowers us with the following breakthrough inspection capabilities:

The LM-1100 is equipped with a 20-megapixel ultra-high-definition monochrome CMOS sensor and high-resolution double telecentric lenses. This advanced optical technology, combined with a multi-lighting system that automatically switches to the optimal light source based on part characteristics, effectively eliminates optical distortion at image edges. This ensures precise capture and measurement even for extremely minute part features.

Traditional measurement operations often result in data fluctuations due to differences in operators’ focus habits or point selection. The LM-1100 features built-in Auto-Focus and Auto-Edge Detection algorithms, effectively standardizing the measurement process.

For mass production inspection requirements, efficiency is a core competency. The LM-1100 features powerful Image Navigation and Simultaneous Multi-Part Measurement functions.

The introduction of the Keyence LM-1100 signifies more than just a hardware update; it represents a comprehensive upgrade in NEWTIDE’s service quality:

NEWTIDE firmly believes that continuous investment in advanced technology is key to creating customer value. The implementation of the Keyence LM-1100 has strengthened our hardware capabilities in the field of precision measurement. Looking ahead, we will continue to uphold our corporate spirit of “Striving for Perfection,” dedicated to providing the highest quality products and services.

If you have any requirements regarding precision processing or inspection specifications, please feel free to contact us at any time.

NEWTIDE — Precision in Every Detail.

The Engineering Logic Behind “First Make, Last Break” Meta Description:Why is Pin 1 on an XLR connector designed to protrude

Audio connectors (commonly known as Phone Jacks) are defined by far more than their physical size. Behind each connector lies

🌟Introduction: The Gold Standard of Professional Connectivity In professional audio, broadcast, and stage lighting systems, the XLR connector is far